Description

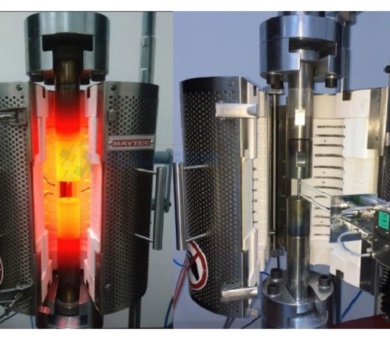

Static and dynamic axial torsion test systems with its experienced engineer staff and offers it to our customers with competitive prices and fast delivery times to meet the requirements of your most special projects.

electromechanical axial torsion test machines are designed to determine the torsional behavior of the specimen when subjected to axial force and can be produced in different torque capacities and axial capacities.

The rotation angles can be changed according to the standards. electromechanical axial torsion testing machines often have system designs that can rotate 360 degrees.

It provides very precise control thanks to the closed loop system controlled by servo motors.

Electromechanical Axial Torsion Testing Machines Features:

- Linear motion is provided by high precision ball shaft according to force capacity.

- Crosshead motion is provided by servo motor through ball shafts.

- Digital electronic controller allows to control torque, angle, force and axial displacement at the same time.

- The software has boot option.

- Software initially measures load, displacement, torque, angle, moment meter. As a result of the test; It allows you to obtain maximum torque, yield strength, breaking angle, breaking force, torque strength in different formats.

- It is designed according to user needs as floor type or desktop bodies in vertical or horizontal directions.

- Axial Capacity (kN): 1 – 10000

- Torque Capacity (Nm): 1 – 10000

- The systems are designed for static and dynamic axial torsion tests.

- Torque and force measurements are made with multi-axis torque-force sensors

Axial Torsion Testing Machines can perform procedure-controlled tests in the form of torque-controlled tests, angle-controlled tests, force-controlled tests, displacement-controlled tests and combinations of these control types.

Electronic Axial Torsion Universal Testing Machines are designed and produced by engineers according to user needs. User can choose torque and force capacity according to their own standards. Different test fixtures and accessories can be designed and offered to customers.

Reviews

There are no reviews yet.